Description

| Material | Modulus of elasticity | ||

|---|---|---|---|

| Poisson’s ratio | |||

| Geometry | Cross-section | Thickness | |

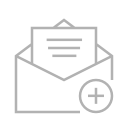

| Boundary conditions | At bottom edge | ||

| Loads | On top edge | ||

| Mesh | Maximum element size | ||

| Minimum element size |

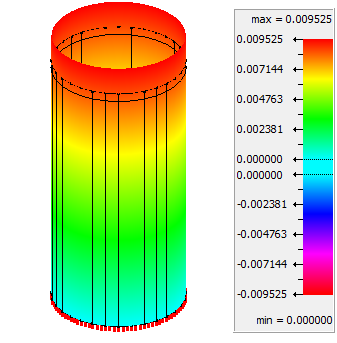

Results

Deformation ![]() in Diamonds

in Diamonds

| Point | Which result | Independent reference | Diamonds | Difference |

|---|---|---|---|---|

| mid | stress |

0,5N/mm² | 0,5N/mm² | 0,00% |

| max | Longitudinal deformation |

0,009524mm | 0,009525mm | 0,01% |

| max | Radial deformation |

0,000714mm | 0,000750mm | 5,00% |

References

- Mécaniciens, S. F. D. (1990). Guide de validation des progiciels de calcul des structures: SSLS 07: cylindre mince sous charge axiale uniforme.

- Roark, R. J., & Young, W. C. (2002). Roark’s Formulas for Stress and Strain (7th edition, Table 13.1 case 1a). McGraw-Hill Companies.

- Tested in Diamonds 2023r01.