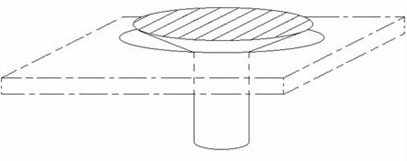

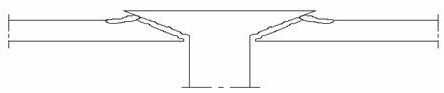

What is punching

Punching is the failure of a plate submitted to a concentrated load. The element causing the load is punched through the plate. The failure surface is conical: punching cone.

|

|

How to calculate the punching shear reinforcement

In case of a footing

- The punching shear reinforcement is automaticaly calculated in the general reinforcement design

.

.

In all other cases

- Calculate the reinforcement

or F2.

or F2. - Go to the reinforcement results

and activate the button for the punching reinforcement

and activate the button for the punching reinforcement  .

. - First select the point, then select all surrounding plates.

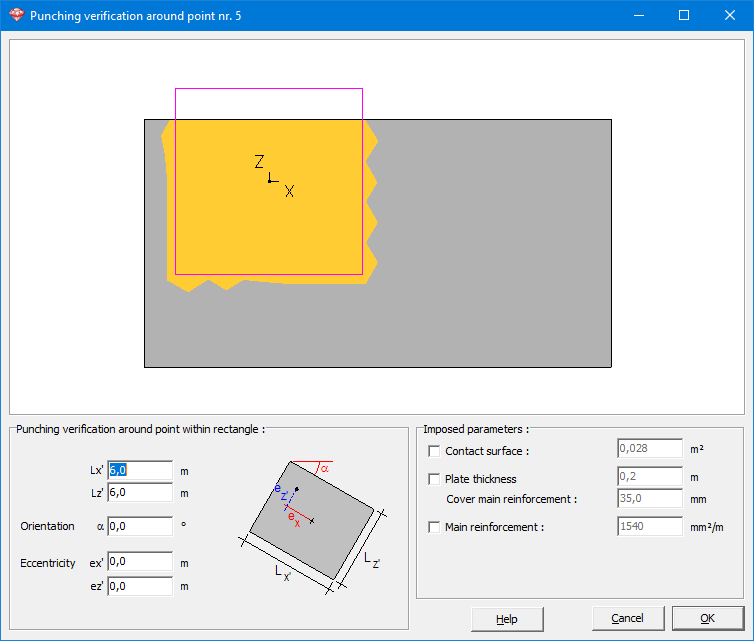

If you select the surrounding plates first, it becomes hard to see if the point is selected or not. - Click once with the right mouse button. The dialog below opens. Here you:

- Click OK to start the calculations.

- The result is a reinforcement amount in mm² per m² plate surface. The amount can be destributed over a circular or an rectangular pattern. Ask a detailed view

to hoover over the results and see the distances to were the punching shear reinforcement should be placed.

to hoover over the results and see the distances to were the punching shear reinforcement should be placed.

Notes:

- Be cautious when the columns/ point loads causing punching are close to each other. Diamonds will not take any overlap of the punching cones into account.

- When you modify a value and you’re satisfied with the punching reinforcement, don’t forget to actually implement that change in the model.